Figure: Current Consumption of A3028As.

| SEP-13 | OCT-13 | NOV-13 | DEC-13 |

| JAN-14 | FEB-14 | MAR-14 | APR-14 | |

| MAY-14 | JUN-14 | JUL-14 | AUG-14 | |

| SEP-14 | OCT-14 | NOV-14 | DEC-14 |

| JAN-15 | FEB-15 | MAR-15 | APR-15 | |

| MAY-15 | JUN-15 | JUL-15 | AUG-15 | |

| SEP-15 | OCT-15 | NOV-15 | DEC-15 |

| JAN-16 | FEB-16 | MAR-16 | APR-16 | |

| MAY-16 | JUN-16 | JUL-16 | AUG-16 | |

| SEP-16 | OCT-16 | NOV-16 | DEC-16 |

| JAN-17 | FEB-17 | MAR-17 | APR-17 | |

| MAY-17 | JUN-17 | JUL-17 | AUG-17 | |

| SEP-17 | OCT-17 | NOV-17 | DEC-17 |

| JAN-18 | FEB-18 | MAR-18 | APR-18 | |

| MAY-18 | JUN-18 | AUG-18 | SEP-18 | |

| OCT-18 | NOV-18 | DEC-18 |

| JAN-19 | FEB-19 | MAR-19 | APR-19 | |

| MAY-19 | JUN-19 | JUL-19 | AUG-19 | |

| SEP-19 | OCT-19 | NOV-19 | DEC-19 |

Archive of aging tests. We stop keeping this table in February 2020, and switched to paper records maintained by our quality control group, rather than have duplication of data in this page. We have roughly five transmitters poaching at all times.

The following table summarizes our recent accelerated aging tests. For older tests see our archives. All tests in water in a sealed jar. Failures recorded on the day they are first detected. An "artifact" is a severe corruption of the EEG signal that appears after the start of the test. Examples of severe corruption are: gain versus frequency for 100-kΩ source is wrong by more than 3 dB, steps changes of ≥100 μV once every ten seconds, dynamic range compressed to less than 10 mV. A "failure" is a failure to transmit an EEG signal, however corrupted that signal might be by artifacts. Search the notes below with the transmitter serial number to get the details of each transmitter we poached.

In the first tests, we did not take note of how we cooled the devices when we removed them from the oven to check them. In some tests we deliberately put them straight into cold tapwater to cool them rapidly. When three such transmitters failed within minutes of cooling, we suspected that thermal shock was a factor in the failures. For several months, we removed the devices from their poaching water and let them cool in air before testing. The resistive switch problem persisted, however, which suggests it is caused by condensation, not contraction. The resistive switch problem turned out to be due to dendrites growing between the pins of U1. We no longer take any particular precautions heating and cooling transmitters to and from 60°C, but we monitor their behavior during and after such changes, so as to catch failures that occur during expansion or condensation.

[15-NOV-16] Seven dual-channel A3028A mouse transmitters provided full performance in 80°C water for 11 days, during which corrosion equivalent to at least 660 days at 37°C took place. Four single-channel A3028E rat transmitters survived corrosion equivalent to at least 940 days at 37°C over the course of ten weeks at 60°C and 80°C. We conclude that that our transmitters will survive corrosion within an animal body for two years. This corrosion lifetime is separate from the operating life of the battery, which is set by the battery capacity and the transmitter's current consumption.

| Circuit | Battery | Qty | Start | First Artifact (days) |

First Failure (days) |

Comments |

|---|---|---|---|---|---|---|

| RV1 | BR2330 | 8 | 09MAR15 | 21 | 35 | 60°C Mostly CC failures, no FL. Thermal shock possible during checks. |

| AV3 | BR1225 | 9 | 12MAY15 | 9 | 9 | 60°C Some CC, some UD, some FL21d. Thermal shock possible during checks. |

| RV1 | BR1225 | 8 | 23JUN15 | 11 | 18 | 60°C Some CC, some UD, some FL21d. Thermal shock always. |

| AV4 | BR1225 | 1 | 15SEP15 | 19 | 19 | 60°C TX1.1: UD19d. Thermal shock always. |

| AV4 | BR2330 | 1 | 30SEP15 | 17 | 22 | 60°C E88.5: CC22d. Thermal shock always. |

| AV4 | BR2330 | 2 | 09OCT15 | 14 | 14 | 60°C E89.1: CC14d. E89.2: RS14d. Thermal shock always. |

| AV3 | BR2330 | 1 | 20OCT15 | 21 | 34 | 60°C E90.14: RS34d, fine after drying. |

| AV4 | BR2330 | 2 | 17NOV15 | 7 | 17 | 60°C E93.2: RS7d. E93.9: RS14d, CS17d. |

| AV3 | BR1225 | 8 | 25NOV15 | 12 | 5 | 60°C Rotated and three coats of MED10-6607. B91.1: GE13d, UD16d. B91.2: CC16d. B91.3: UD5d. B91.10: RS9d. B91.6: CS9d. B91.9: UD12d. B91.8: GE12d, CC16d. B91.12 FL23d. |

| AV5 | BR1225 | 2 | 08DEC15 | 25 | 25 | 60°C C94.3: UD25d. C94.4: UD25d. |

| AV5 | BR2330 | 2 | 11DEC15 | 11 | 11 | 60°C E94.12: RS11d. E94.3: RS12d |

| AV5 | BR1225 | 2 | 22DEC15 | 17 | 17 | 60°C C96.4: CD17d. C96.5: UD29d. |

| AV5 | BR2330 | 2 | 28DEC15 | 28 | 31 | 60°C E97.2: UD37d. E97.3: UD31d. |

| AV5LF | BR2330 | 1 | 12JAN16 | 14 | 14 | 60°C E98.13: CC14d. |

| AV5LF | BR2330 | 2 | 02FEB16 | 45 | 45 | 60°C E100.13: UD45d, E100.14: UD66d. |

| AV5LF | BR1225 | 3 | 09FEB16 | 9 | 13 | 60°C C101.11: FL39d, C101.13: UD22d, B102.12: TM13d. |

| RV2 | BR2330 | 2 | 10MAR16 | 27 | 32 | 60°C R105.12: CC32d, R106.10: CC69d. |

| AV5LF | BR2330 | 2 | 30MAR16 | 36 | 36 | 60°C E107.9: UD48d, E108.8: CC36d. |

| AV5LF | BR1225 | 2 | 06APR16 | 19 | 19 | 60°C B108.14: UD19d, B109.3: FL26d. |

| RV3 | BR1225 | 2 | 29APR16 | 14 | 19 | 60°C C110.13: UD25d, C110.14: UD19d. |

| RV3 | BR2330 | 1 | 17MAY16 | 7 | 14 | 60°C R112.11: RS14d. Hand-made, no epoxy top-coat, 5 coats MED10-6607. |

| RV3 | BR2330 | 2 | 24MAY16 | 40 | 125 | 60°C E113.9 (24th): CC125d, E113.10 (27th) FL125d. Rotator, 3 coats MED10-6607. |

| RV3 | BR1225 | 2 | 31MAY16 | 27 | 27 | 60°C B113.13: FL27d, B114.4: FL27d. Rotator, 4 coats MED10-6607. |

| RV3 | BR2330 | 2 | 09JUN16 | 31 | 61 | 60°C R114.10: CC78d, R114.11: CC61d. Rotator, 5 coats MED10-6607. |

| RV3 | BR2330 | 2 | 14JUN16 | 55 | 104 | 60°C E115.12: UD107d, E116.4: RS104d. Rotator, 3 coats MED10-6607. |

| RV3 | BR1225 | 2 | 09AUG16 | 27 | 27 | 60°C B121.13: FL27d, B122.11: FL27d. Rotator, 5 coats MED10-6607. |

| RV3 | BR2330 | 4 | 05SEP16 | 59 | 60 | 60°C until 27OCT16, then 80°C. R124.9 CC63d, E126.8 TS60d, E127.1 CC65d, E127.11 UD71d. Rotator, 5 coats silicone. |

| RV3 | BR2330 | 1 | 16SEP16 | 56 | 56 | 60°C until 27OCT, then 80°C. R129.2 TS56d. Rotator, 3 coats SS-5001 silicone. |

| RV3 | BR2330 | 2 | 30SEP16 | 12 | 12 | 60°C until 27OCT, then 80°C. R129.5 UD53d, R129.7 FE12d. Rotator, 5 coats MED10-6607, wrinkles and noise. |

| RV3 | BR1225 | 2 | 30SEP16 | 28 | 28 | 60°C B129.14 FL28d, B130.9 FL28d. 4.5 coats MED10-6607, wrinkles. |

| RV3 | BR1225 | 7 | 27OCT16 | 11 | 11 | 80°C A135.1 TS13d, A135.3 CC13d, A133.5 FL15d, A135.7 UD13d, A135.9 RS11d, A134.11 CC13d, A134.13 UD13d, 1 coat SS-5001. |

| RV3 | BR1225 | 2 | 16DEC16 | 22 | 91 | 60°C/80°C B146.8 CC91d, B146.9 CC91d. Test of shelf life: turned off. 1 coat SS-5001. |

| RV3 | CR2450 | 2 | 17FEB17 | 11 | 31 | 80°C Q154.56 CS31d, Q154.73 UD31d. 1 coat SS-5001. |

| RV3 | BR2330 | 2 | 17FEB17 | 11 | 31 | 80°C E144.10 CC31d, E150.6 CS31d. 1 coat SS-5001. |

| RV3 | BR2330 | 2 | 17MAR17 | 15 | 27 | 80°C E153.7 UD35d, 1 coat SS-5001. E154.1 UD27d, 2 coats SS-6001. |

| RV3 | BR2330 | 2 | 13APR17 | 19 | 36 | 80°C R129.6 CC39d, 5 coats MED10-6607. E153.14 CC36d, 2 coats SS-6001. |

| RV3 | BR2330 | 4 | 19MAY17 | 14 | 14 | 80°C E146.2 CC33d, E154.3 UD26d, E155.21 CC26d, E155.22 UD14d. 1 coat SS-5001 + 1 coat MED10-6607 after 2 months. |

| RV3 | BR2330 | 2 | 23JUN17 | 18 | 39 | 80°C E201.57 CC39d, E201.61. UD39d. 1 coat SS-5001 + 1 coat MED10-6607 after 2 hrs. |

| RV3 | BR1225 | 1 | 04AUG17 | 14 | 14 | 80°C C201.102 UD14d. 1 coat SS-5001 + 1 coat MED-6607 after 2 hrs. |

| RV3 | BR2330 | 1 | 04AUG17 | 21 | 35 | 80°C E201.114 CC35d. 1 coat SS-5001 + 1 coat MED-6607 after 2 hrs. |

| RV3 | LiPo | 2 | 08SEP17 | 10 | 10 | 80°C No1 FL10d, No3 FL10d. 19 mA-hr Battery. 1 SS-5001 + 1 MED-6607 after 2 hrs. |

| RV3 | LiPo | 1 | 08SEP17 | 4 | 4 | 80°C No5 OG4d. 190 mA-hr Battery. 1 SS-5001 + 1 MED-6607 after 2 hrs. |

| RV3 | LiPo | 1 | 03OCT17 | 66 | 70 | 60°C ER.8 UD70d. 190 mA-hr Battery. 3 MED-6607. |

| RV3 | BR1225 | 2 | 03NOV17 | 14 | 14 | 60°C U201.161 FL14d, U201.163 FL14d. 3 MED-6607. |

| RV3 | BR1225 | 2 | 14NOV17 | 15 | 15 | 60°C J204.45 FL15d, J204.49 FL15d. 3 MED-6607. |

| RV3 | BR2330 | 2 | 05DEC17 | 31 | 41 | 60°C G201.183 FL43d, G201.185 FL41d. 3 MED-6607. |

| GV1 B73028 | BR1225 | 10 | 16JAN18 | 3 | 6 | 80°C, J3 CC6d, J13 UD6d, J5/J21 UD13d, J1/J7/J9/J11/J17/J19 FL14d. Nominal 15d. |

| GV1 B73028 | BR1225 | 3 | 06MAR18 | none | 24 | 60°C, B200.78 FL24d, B200.81 FL24d, B200.82 FL24d. Nominal 26d. |

| GV1 B73028 | BR1225 | 2 | 16MAR18 | none | 27 | 60°C, B205.9 FL27d, B205.13 FL28d. Nominal 26d. |

| RV3 B69610 | BR2330 | 1 | 17APR18 | NA | 113 | 60°C, E206.130 TS113d. Nominal 130d. |

| GV1 B75204 | BR2330 | 1 | 07MAY18 | none | 85 | 60°C, E200.119 TM85d. Nominal 130d. |

| PV1 B78457 | CR1025 | 1 | 07MAY18 | 11 | 12 | 60°C, P1.90 FE12d. Nominal 36d. |

| PV1 B78457 | CR1025 | 1 | 29MAY18 | none | 10 | 60°C, P1.89 UD10d. Nominal 36d. |

| GV1 B75204 | BR1225 | 1 | 27JUL18 | none | 7 | 60°C, B200.91 TS7d. Noisy. Nominal 26d. |

| GV1 B75204 | BR1225 | 4 | 27JUL18 | none | 24 | 60°C, B202.61 FL24d, B207.30 FL24d, B207.33 FL25d, and B207.34 FL25d. Nominal 26d. |

| PV1 B78457 | CR1025 | 2 | 19SEP18 | none | 26 | 60°C, P207.41 UD26d, P207.45 FL33d. Nominal 36d. |

| GV1 B78082 | BR1225 | 1 | 16OCT18 | none | 24 | 60°C, B206.193 FL24d. Nominal 26d. |

| GV1 B78082 | BR1225 | 2 | 16OCT18 | none | 34 | 60°C, C206.157 FL34d, C210.7 FL41d. Nominal 40d. |

| GV1 B78082 | BR2330 | 1 | 02NOV18 | none | 91 | 60°C, E210.25 CC91d. Noisy. Nominal 130d. |

| GV1 B78082 | BR1225 | 2 | 20NOV18 | 30 | 31 | 60°C, C210.43 FL36d, C210.56 UD31d. Nominal 40d. |

| PV1 B78457 | ML621 | 3 | 10DEC18 | none | 6 | 60°C, T19 FL6d, T20 FL6d, T21 FL6d. Nominal 6.5d. |

| GV1 B78082 | BR2330 | 2 | 18DEC18 | 91 | 300 | 60°C, Inactive Test, D208.189 UD355d, D208.193 TS200d. 1 SS-5001, 1 MED-6607. |

| PV1 B78457 | ML621 | 3 | 21DEC18 | 6 | 7 | 60°C, T19 FL7d, T20 FL7d, T21 FL7d. Nominal 6.5d. |

| PV1 B78457 | CR1025 | 1 | 21DEC18 | none | 23 | 60°C, P207.73 UD23d. 3 MED-6607. Nominal 36d. |

| PV1 B78457 | ML621 | 3 | 31DEC18 | NA | 15 | 60°C, Inactive Test, T19 CC64d, T20 UD15d, T21. |

| Circuit and Build |

Battery | Start | First Artifact (days) |

First Failure (days) |

Comments |

|---|---|---|---|---|---|

| GV1 B78082 | BR1225 | 10JAN19 | none | 33 | 60°C, K207.65 CS42d. Nominal 58d. |

| GV1 B78082 | BR1225 | 10JAN19 | none | 33 | 60°C, K207.68 UD33d. Nominal 58d. |

| PV1 B79594 | CR1025 | 15JAN19 | NA | 34 | 60°C, P207.105 UD34d. Nominal 36d. |

| PV1 B79594 | CR1025 | 18JAN19 | 31 | 103 | 60°C, Inactive Test, P207.114 CC103d. |

| PV1 B79594 | BR1225 | 05MAR19 | none | 12 | 60°C, S210.67 CC. Soldered batteries. Nominal 40d. |

| PV1 B79594 | BR1225 | 05MAR19 | 12 | 41 | 60°C, S210.78 FL. Soldered batteries. Nominal 40d. |

| PV1 B79594 | BR1225 | 05MAR19 | none | 9 | 60°C, S210.68 FL. Soldered battery. Nominal 8d. |

| GV1 B81441 | BR1225 | 16APR19 | none | 20 | 60°C, B210.155 FL. Left on 1-5 days during encapsulation. Nominal 26d. |

| GV1 B81441 | BR1225 | 16APR19 | none | 27 | 60°C, B210.167 FL. Noisy. Nominal 26d. |

| GV1 B81441 | BR1225 | 28MAY19 | none | 24 | 60°C, B205.59 FL. |

| GV1 B81441 | BR1225 | 28MAY19 | none | 27 | 60°C, B211.25 FL. |

| GV1 B85211 | BR2330 | 22JUL19 | none | 102 | 60°C, E200.125 UD. Nominal 130d. |

| GV1 B85211 | BR2330 | 22JUL19 | 126 | 140 | 60°C, E200.126 FL. Nominal 130d. |

| GV1 B85211 | BR1225 | 13AUG19 | none | 37 | 60°C, C207.137 FL. Nominal 40d. |

| GV1 B87434 | BR2330 | 30SEP19 | none | 77 | 60°C, E200.173 UD. Nominal 130d. |

| GV1 B85211 | BR1225 | 30SEP19 | none | 25 | 60°C, B211.34 FL. Nominal 26d. |

| GV1 B85211 | BR1225 | 30SEP19 | none | 28 | 60°C, B211.36 FL. Nominal 26d. |

| GV1 B87434 | BR1225 | 01NOV19 | none | 33 | 60°C, C213.3 FL. Nominal 33d (60 μA). |

| PV1 B79594 | CR1025 | 25NOV19 | 19 | 19 | 60°C, P204.52 UD. Soldered battery. Nominal 36d. |

| GV1 B87434 | BR2477 | 20DEC19 | 74 | 133 | 60°C, L213.43 UD. Nominal 167d. |

| GV1 B87434 | BR2477 | 20DEC19 | 84 | 144 | 60°C, L213.51 TS. Nominal 167d. |

| PV1 B79594 | BR1225 | 03JAN20 | 37 | 40 | 60°C, S213.65 FL. Soldered battery. A3028S2, nominal 40d. |

| PV1 B79594 | BR1225 | 03JAN20 | none | 17 | 60°C, S213.68 CW. Soldered battery. A3028S2, nominal 40d. |

| GV1 B87434 | BR2330 | 10JAN20 | none | 102 | 60°C, E213.74 CC. Nominal 130d. |

| GV1 B87434 | BR1225 | 27MAR20 | none | 40 | 60°C, C213.197, FL. Nominal 40d. |

| GV1 B87434 | BR1225 | 27MAR20 | 34 | 40 | 60°C, C213.210 FL. Nominal 40d. |

| GV1 B87434 | BR1225 | 01MAY20 | none | none | 60°C, B216.2 FL. Nominal 26d. |

| PV1 B79594 | CR1025 | 05AUG20 | none | 32 | 60°C, P204.54 FL. Nominal 35d. |

| PV1 B79594 | CR1025 | 05AUG20 | 15 | 21 | 60°C, P204.57 CS. Nominal 35d. |

| GV1 B95447 | BR2330 | 07SEP20 | none | 122 | 60°C, E204.98 FL. Nominal 130d. |

| GV1 B95447 | BR2330 | 07SEP20 | 74 | 110 | 60°C, E204.99 FL. Nominal 130d. |

| GV1 B95447 | BR1225 | 05OCT20 | none | 25 | 60°C, B205.45 FL. Nominal 28d. |

| GV1 B95447 | BR1225 | 05OCT20 | none | 25 | 60°C, B205.49 FL. Nominal 28d. |

| GV1 B87434 | BR1225 | 09OCT20 | 21 | 27 | 60°C, C207.189 UD. Nominal 40d. |

| GV1 B87434 | BR1225 | 05-JAN-21 | none | 36 | 60°C, C217.88 FL. Nominal 40d. |

| HV1 B99345 | BR1225 | 01-FEB-21 | none | 24 | 60°C, S217.59 UD. Nominal 40d. |

| GV1 B95447 | BR1225 | 01FEB21 | none | 28 | 60°C, B205.75 FL. Nominal 28d. |

[19-SEP-13] Receive 10 assembled A3028 circuit boards. Measure quiescent current with external battery and power switched off to circuit. We program all ten with their channel numbers, channel X enabled at 512 SPS, channel Y disabled. We calibrate the ring oscillators and find that the bit rate is 200±5 ns for tcd_divisor = 24 for all ten. We set frequency_low to 8 for all transmitters. We cannot calibrate the center frequencies today because our spectrometer is broken. We obtain over 90% reception with the MAX2624 held against a receiving antenna. All transmitters detect mains hum. Current consumption results in table below.

We solder a battery to the board. We find that P3-4 is not connected to 0V, so we connect it with a wire. With a jumper across P3-3 and P3-4, we can switch on and off the circuit. But without this jumper, R1 keeps transistor U1-1 turned off so the battery is disconnected from the circuit. The only current flowing is through 10 MΩ to 0V, which is around 0.27 μA.

[20-SEP-13] Create the first two-channel 512 SPS transmitter: the calibrated A3028A with leads shown here. Operating current is 132 μA. We re-program to create a one-channel 512 SPS transmitter and operating current is 76 μA. Thus we have a 20-μA base current plus 0.11 μA/SPS. We test both inputs of the A3028A and find they track almost exactly one another when we apply the same mains hum or heart beat. Input noise is 20 counts rms on each, which is only 8 μV rms.

Disabling the three test point outputs drops the operating current by 2±1 μA for 512 SPS and 1024 SPS. We resolve not to disable the test points because doing so complicates the calibration process.

[24-SEP-13] We load a battery into prototype A3028A transmitter 32.2, which has channel numbers 2 and 3. We apply acrylic conformal coating. We must jumper P3-3 to 0V to get the battery to connect. We measure the frequency response of both channels, as shown here. We clip off the programming extension. The transmitter now turns on and off, and picks up mains hum. We encapsulate in black epoxy and leave to cure.

[25-OCT-13] Four out of our nine un-encapsulated A3028As will not switch on. We trace the problem to the BGA-5 package of U3. We re-heat these chips, but they simply come off on the iron. Their solder blobs appear to have broken off the package. Since we first tested the circuits we have applied acrylic coating and loaded batteries. Several weeks have gone by. In a loupe, we see the ball of U3-2 appears to be convex at the package, as if it has broken off. Torquing the board during depanelization might be the cause of such a problem, or a flaw in the package construction.

We send the above photographs to the company that assembled the circuit to see if they have any ideas about what went wrong. We replaced U3 on 32.4, 32.6, 33.2, and 33.4. The others, 32.8, 32.10, and 32.12, which were not faulty, we leave as they are. We program all of them as A3028As. Current consumption is 2.5±0.2 μA when inactive and 145±5 μA when awake.

[28-OCT-13] Our No32.2 encapsulated A3028A has been in water for over three weeks. The gain of both channels is nominal through the pass-band, and in agreement to within ±0.5 dB or better.

[31-OCT-13] At ION, we find that No32.2 transmits only 256 SPS per channel. When we measured its frequency response, we were measuring the response of its low-pass filters, but above 128 Hz we must have been seeing an aliased version of the input sinusoid.

[05-NOV-13] We have seven encapsulated A3028As and A3028Ds. Their programming extensions are still attached. If we apply the jumper between P3-3 and P3-4, we can run the transmitter of its own battery. We remove the jumper and apply an external battery through an ammeter and measure the sleeping and active current consumption. If we run one of the A3028As for several minutes minutes using its own battery, and then switch to using an external battery, the sleep current immediately after the switch is 80 μA. Within thirty seconds the sleep current has dropped to 40 μA. Within ten minutes, it is back to the original 2.1 μA. We do not observe this jump in sleep current with the A3028D.

The A3028A is equipped with the BR1225 battery. When we draw 145 μA from this battery, its voltage drops from 2.8 V to around 2.6 V. Our external battery is 3.0 V. We suspect that the U1 p-channel mosfet's parasitic diode is conducting tens of microamps from the external to the internal battery while the internal battery recovers to 2.8 V.

[18-NOV-13] We have A3028A transmitters 33.2, 33.4, and 33.6 in water. They measure 14.0 mm x 13.5 mm x 7.4 mm, with variations due to lumps, but these are the average values as best as we can guess. This puts the volume at less than 1.4 ml.

[20-NOV-13] We have A3028D transmitters 32.6, 32.8, 32.10, and 32.12 encapsulated. We measure their frequency response, and find it most satisfactory. We put them in water.

[25-NOV-13] Transmitters 32.6, 32.8, 32.10, 32.12, 33.2, 33.4, and 33.6 have been soaking in water for at least four days. All these were made with acrylic coating on the amplifiers while masking the battery pads, then soldering the battery with no-clean flux. We turn them on, put them in our faraday enclosure while still in water and record the input noise. A3028Ds have average input values around 45k, while A3028As have average around 47k. This suggests battery voltage 2.6 V for the BR2330 batteries on the A3028Ds and 2.5 V for the BR1225 batteries on the A3028As. The temperature in our office is around 17°C, so these values are consistent with the battery data sheets.

We remove from water and lay on a towel in the faraday enclosure. We see no square waves. We measure frequency response. The gain of each channel is always within 0.2 dB of its partner in the same transmitter. Soon after turning on our function generator and removing the transmitters form water, we measure the gain of all transmitters to be 2 dB too hight from 1-20 Hz. Half an hour later, all transmitters have the same gain we measured before the soak. We cool the transmitter with freezer spray and heat them in hot water, but observe no change in their frequency response.

[18-DEC-13] A few weeks ago we received 100 of A3028 assembled circuits from an assembly company. Out of the bag, one in five will not stay switched on. This is the same problem we observed on 25-OCT-13. We take 17 circuits that work and put them through four cycles of 5°C-60°C. One of the seventeen does not work at the end. The faulty circuits will work if we push down on U3, the BGA-5, with a stick. We replace U3 on two faulty circuits and they both work afterwards. We send six faulty circuits back to the assembly company, along with apparatus for observing the fault with the switch. We calibrate sixteen working circuits and load wires, antennas, and batteries. Today thirteen out of sixteen have the switch problem. We replace U3 on five of them, and they all work now. We photographed one of the BGA-5s we removed, next to its footprint.

In the photograph we see two balls with flat tops on the footprint. On the component there are three pads with solder residue and two with no solder residue. These two match the flat-topped solder balls. We suppose that the balls broke away from the package during electronic assembly and subsequently failure takes place when oxide builds up between the two surfaces. We resolve to replace all the BGA-5s before calibration.

From ION, we receive the first report from Rob Wykes of recordings made with an A3028D implanted in a rat, see here.

[20-DEC-13] We replace U3 on another eleven A3028 circuits. All fo them now work perfectly. In three transmitters we found problems arising from excessive solder on the battery joints.

[24-DEC-13] Transmitters 32.2 and 32.6 have been in water for over five weeks and show no sign of the square wave problem. These were made with acrylic coating and no-clean flux for the battery terminals.

[31-DEC-13] We modify the P3028A01.abl firmware so that the transmit clock (TCK) waveform mark-space ratio is always 50%. We create P3028A02.abl. We do this at the expense of resolution in the period. With transmitter 34.7 we measure TCK period with divisor.

We cool a transmitter with freezer spray. Its internal temperature drops to around −20°C. Its transmit clock period drops from 207 ns to 200 ns. This suggests of order 1% drop in the logic propagation delay per 10°C drop in temperature.

We test 4 A3028Ds and 11 A3028As with epoxy and varnish encapsulation. All have their programming extensions. We power them with their own batteries by means of a jumper from !ON to 0V. We attempt turn them on and off with a magnet half a dozen times each. One transmitter, A3028D No36.1, will not turn off. All others turn on and off normally. In two transmitters we find the RF frequency is higher than 918 MHz, so we bring it down by 4 MHz. In one we find the TCK period is below 195 ns so we increase it to 207 ns. In one the TCK period is correct but the mark-space ratio is only 46%. We fix the mark-space ratio. There are two transmitters marked 34.7.

We vary the transmit clock period of transmitter 34.7 and some others, and record reception for all transmitters after measuring their period. We obtain the following graph showing how reception varies with transmit clock period, provided that the mark-space ratio is between 48-52%. It looks like the period must lie within the range 195-210 ns for reliable reception. We make sure that all 15 of the A3028s lie within this range.

While testing the transmitters, we place each one on our spectrometer's Damped Loop Antenna (A3015C). We observe power at the transmitter's center frequency of −26 dBm. Our interference power peaks at −45 dBm, and we obtain good reception so long as interference is 10 dB less than our signal, so we are certain obtain reliable reception with the A3028 on the loop antenna.

[07-JAN-14] We have 14 of A3028 encapsulated. This batch has un-stretched springs for leads, so they are more flexible, and the silicone coating is thinner. We turn them all off, put them in a box and shake them around together. Some of them turn on. We turn them off, place them apart on our bench and pick each one up and handle it and tap it. None of them turn on. We put them together in a box and some of them turn on. It appears that some of the batteries on these transmitters have become magnetic, so that transmitters can turn one another on and off.

We measure frequency response of all 14 transmitters. All are within 1 dB of nominal, and the pairs of channels match to within 0.2 dB. All turn on and off several times with a magnet. We leave them turned off soaking in water. There remains fifteenth transmitter, No36.1, that won't turn off. We place it in our isolation chamber to be part of our reception experiments. We will leave it running continuously from today to see how long it will last. It has already been running since 31-DEC-13.

[13-JAN-14] Our 14 transmitters have been soaking for 5 days. We also have No32.6, which has been soaking for several weeks. No34.9 has good frequency response but poor reception (75%). We measure its transmit clock period to be 190 ns, which is too low. No34.5 produces a square wave on its No6 input, which is its X input. All other transmitters: 32.6, 34.1, 34.3, 34.7, 34.11, 34.13, 35.3, 35.5, 35.7, 35.9, 35.11, 35.13, and 36.7 have perfect frequency response and good reception. We put No34.5 in the oven at 60°C.

We discover a bug in the P3028 firmware: the Y channel is the lower-number of the two channels, when our expectation was that it would be the higher-number of the two channels. We will leave things as they are for now, until we have shipped the 20 dual-channel transmitters ordered in Job 1141. Then we will correct the problem.

[14-JAN-14] No34.5 has good reception and perfect frequency response today, after a bake of several hours yesterday.

[17-JAN-14] After a few days in water, No34.5 has poor reception, and sensitivity of No6 channel to mains hum appears higher. No square wave.

[21-JAN-14] No34.5 is square waving again, and has poor reception. The square wave appears on both channels. We turn it off, let it sit for a few minutes in air, turn it on again, and it no longer generates a square wave, but reception is still poor.

[12-FEB-14] No36.1 has been running since 31-DEC-13 and is still going strong.

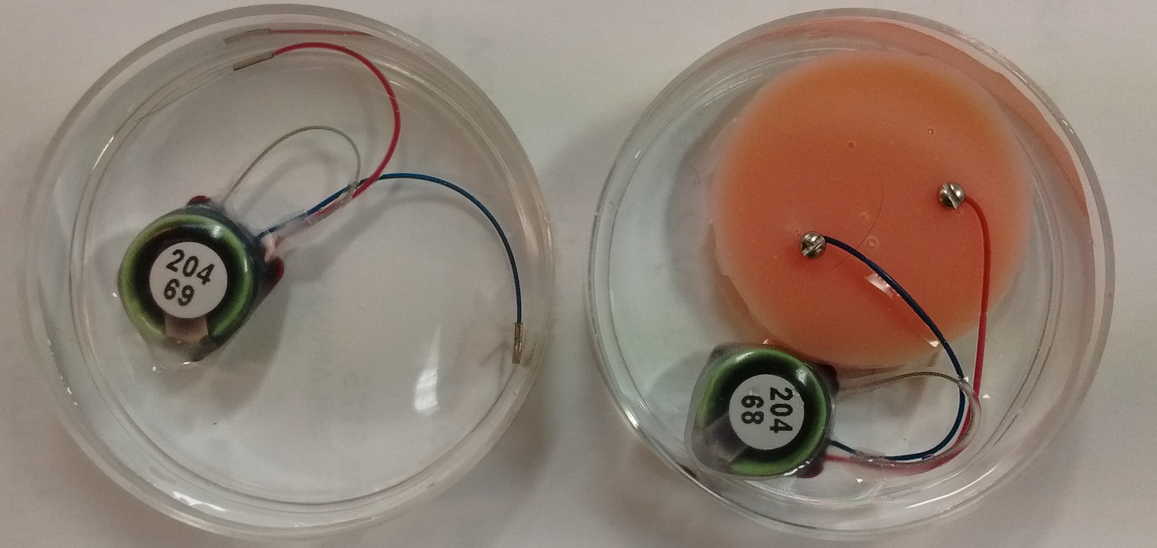

[21-FEB-14] Shown below is the thermoplastic over-molded A3028A with four coats of silicone, compared with our own epoxy-encapsulated A3028A with four coats. The silicone went on the thermoplastic very well, but we messed up the final two coats with dry air.

The over-molded device has exterior dimensions approximately 15.0 mm × 15.0 mm × 9.0 mm = 2.2 ml, while the epoxy encapsulated device has exterior dimensions 14.0 mm × 14.0 mm × 9.0 mm = 1.8 ml. We would like to reduce the width of the over-mold by 1 mm if possible. We place the over-molded transmitter in water to measure its switching noise. Both channels have the same 3-μV amplitude switching noise at the exact same 20.75 Hz.

We take out transmitter No34.5 and find that it will no longer turn on.

[25-FEB-14] We examine the A302801B layout and find the most likely place at which moisture-invoked feedback from the output of the EEG amplifiers to their inputs could cause the square wave problem we observed in the A3019, and in No34.5. In the A302801B layout, the X amplifier is on the bottom side and the Y amplifier is on the top. The X input appears on pad U5-3, and ×100X on the CH0 via. These are separated by 1.4 mm. The Y input appears on U6-3, and ×100Y on the CH1 via. These are separated by 0.6 mm. Oscillation occurred with condensation in the A301901B layout because the input and output of the ×100 amplifier were separated by 0.6 mm. But in No34.5, X was oscillating, not Y. The ×100X appears on R11, which is 0.7 mm from the X input pad. If there were residual acid flux around the X and Y input pads, and combining with condensation, it would cause oscillations in X rather than Y. Another potential source of oscillation is the 0.5-mm separation between the X on U5-5 and ×40X on R8, and between Y on U6-3 and ×40Y on R15.

[27-FEB-14] We have a batch of thirteen A3028Es, rat-sized single-channel. Load batteries with no-clean water-soluble flux. Wash in hot water. Bake. One won't turn on, drawing 44 mA from the battery. Replace U9, re-calibrate RF center frequency and it works. Clip extension in preparation for programming and note clipping requires us to torque the board up from the battery and sends a shock through the circuit board.

New firmware P3028A03 provides the correct channel numbers for X and Y in the dual channel versions.

[28-FEB-14] Check thirteen A3028Es and all turn on and off, show mains hum.

[03-MAR-14] We take four broken A3019 and A3028 circuits, load BR1225 batteries, and coat them as they are with aerosol acrylic and aerosol silicone conformal coatings. We bake at 60°C for ten minutes, coat again, and bake for 20 minutes. We remove the batteries to see how well the interior components are coated. The coatings have a UV indicator, so we are able to take the picture below in our UV lamp to show where the coating is present.

The large square chip is the logic chip on the top side, beneath the battery. Its top surface is flush with the battery bottom surface when the battery is loaded. The silicone has penetrated between the two surfaces better than the acrylic. Close inspection of the circuits reveals that both coatings cover the circuit board and resistors below the battery. Upon close inspection of all boards, we note many bubbles and imperfections in the acrylic coating, and few imperfections in the silicone. We remove the MSOP-8 package on the top side and observe both acrylic and silicone have covered 90% of the area beneath the package, as shown below.

We load a battery onto an A3028A along with three leads and antenna. We apply three coats of silicone conformal coating. We baked for at least 5 minutes at 60°C between coats and for three hours afterwards. The silicone has coated the circuit board, and had penetrated beneath the larger components, but the corners of the P0402 resistors are bare. We connect an auxiliary battery, turn the transmitter on, and find we can taste the battery voltage on the bottom side of the board. We place the circuit in water and its X and Y channels oscillate together at about 1 Hz.

No36.1, an A3028D, has been running since 31-DEC-13 and is still going strong.

[06-MAR-14] We receive this xray image of the over-molded A3028A from one of our assembly companies. The picture below is a close-up of the space under the battery, with contrast and brightness enhanced to show the cavity beneath the battery wrapper.

The space between the battery body and the top-side components is filled. The spaces between the battery tabs and the battery body are filled. If such wide, thin spaces are filled, we are hopeful that the spaces between P0402 components are also filled.

[10-MAR-14] Transmitter No36.1 is near the end of its life: battery voltage is 2.2 V. It has been running since 31-DEC-13, a total of 70 days, or 10 weeks, which is 2 weeks longer than we guarantee. We put the transmitter in water with the X and Y leads immersed and the C lead outside. We see high-frequency noise as shown below.

This noise is the same as the high-frequency noise that arises on the A3019 when there is a break inside the insulation of the X− lead.

We have 13 transmitters No38.7 through 39.5 (missing 38.6) that have been soaking in water for four days. We test reception and frequency response with 20 MΩ source. All are normal except No39.1 which has poor reception and 38.9, 38.10, and 39.2, which have gain 3 dB below normal at 100 Hz. We connect these three to a 50-Ω source and frequency response for all three is normal. We put all of them in the oven to bake.

We suggest that the low gain described in the previous paragraph is due to a capacitance between the X input and the amplified X, location shown here. The gain is normal at 10 Hz because the capacitor's impedance is much greater than our 20-MΩ source impedance. The gain drops by 3 dB at 100 Hz because the capacitor loads the source with −10j MΩ in parallel with the X input's 10-MΩ input resistor. When we drive the input with a 50-Ω source, the condensation capacitor does not load the source, so the gain is normal at all frequencies.

[12-MAR-14] Our transmitters No38.7 through 39.5 (missing 38.6) have been baked for a few hours. Gain versus frequency is nominal for all 13 transmitters. Our Octal Data Receiver is malfunctioning, giving the impression of poor reception on all channels. We replace the data receiver and all 13 transmitters have perfect reception. We measure switching noise in water.

The switching noise is no more than 6 μV and the frequency is 22±1 Hz. The variation in frequency is five times smaller than for the A3019.

Transmitter 36.1 has battery voltage 2.17 V but is still running after 72 days. It detects mains hum, heart beat from two people, and has normal noise.

[19-MAR-14] Transmitter 36.1 has battery voltage 1.94 V but is still transmitting intermittently. It records mains hum.

[21-MAR-14] We have a batch of nine A3028Es, No39.6-39.14, with 150-mm un-stretched leads. We applied acrylic coating to the critical regions of the A302801B layout. We encapsulate with epoxy, touched up with nail polish, and applied five coats of silicone. The result is a transmitters with average body volume 2.8 ml (we immersed up to the antenna base and measured total displacement of water 24.8 ml). For the past year we have been applying eight coats to rat transmitters, but we now believe eight coats is excessive, because moisture problems do not arise from penetration of the silicone, but rather through condensation inside a sealed silicone coating. We leave in water to soak.

We have a batch of four A3028Bs, No40.1-No40.4, with 50-mm un-stretched leads. We apply acrylic coating, encapsulate in epoxy, coat five times with silicone. Two of these have a gold-plated pin for the X electrode (electrode type F). We leave in water to soak.

[24-MAR-14] Transmitters No39.6-40.4 have been soaking in water for three days. Frequency response of all thirteen transmitters is within 1 dB of nominal at all frequencies. Reception is perfect in our small faraday enclosure. We obtain this plot of switching noise in No39.6-40.4 (One vertical division is 0.8 μV).

We have a yield of 13 out of 13 after a three-day soak. We resolve to ship a batch of 8 A3028Es to ION and a batch of 3 A3028Bs to Edinburgh.

[26-MAR-14] We have completed and double-checked our A302801C layout. We describe the changes and give links to new files here.

[28-MAR-14] We have an A3028A that won't turn off. It's the one we received with over-mold from an assembly company, and it has been running since at least 12-MAR-14 when we first examined it and determined that it was stuck on. So far it has seen 16 days of continuous running, and our expected battery life for this device is 15 days. Battery voltage is 2.52 V. We drop it in water with the lead ends stripped and observe noise 37 counts rms on both channels.

[31-MAR-14] The above-mentioned over molded transmitter is no longer running. Operating life for the A3028A appears to be a little over 16 days.

[11-APR-14] We assemble two A3028P single-channel transmitters for implantation in rat pups. At the moment, they have their programming extensions attached. They are equipped with freshly-charged PP031012AB 19-mA-hr lithium-ion batteries. We obtain this plot of A3028 noise when powered by a lithium-polymer battery, before encapsulation, when we expect no switching noise.

Noise amplitude in counts rms and battery voltage in Volts are as follows; No40.6: 19.4 and 4.3 V, No40.7: 17.5 and 4.3. For comparison we have an A3028A with a fresh, BR2330 battery with No13 34.0 and 3.0, No14 33.0 and 3.0. With battery voltage 4.3 V, one count is 650 nV, and for 3.0 V one count is 460 nV. We expect the noise amplitude to drop from 33 to 23 counts rms when we increase battery voltage from 3.0 to 4.3 V.

The center of the RF spectrum of both A3028Ps lies within 913-918 MHz. The transmit clock period lies within 195-215 ns. Reception in our faraday enclosure is perfect. Dynamic range at the X input is 43 mV. Gain and frequency response is nominal for both devices.

We find burrs on the battery wire solder joints. We re-solder the joints and wash the device with the battery still attached. Both batteries lose voltage. One appears to be discharged and accepts a re-charge. The other will not re-charge. We replace the batteries and epoxy them as before.

[14-APR-14] Transmitters No40.6 and 40.7 look good, but No40.6's battery is drained for reasons we cannot explain. We did not leave the enabling jumper in place, so the battery should have been isolated. We recharge both batteries and monitor their battery voltages through their X measurement with the Receiver Instrument and a 200-Ω resistor draining the battery directly.

The 200-Ω resistor load drains the battery almost the maximum recommended rate. By the time we end the experiment, No6's battery has delivered 12 mA-hr and is down to 2.5 V. The transmitter stops working. No7's battery has delivered 14 mA-hr and its battery voltage is still 3.5 V. The No6 battery has been damaged by over-discharge, but still provides more than half its nominal capacity.

We encapsulate two A3028Ps. One was faulty before, both were faulty after. The first one, No6, draws 800 uA when asleep and 900 uA when awake. Even when asleep, it will drain its battery in about twenty-four hours. This explains why it worked when we first assembled it, then the battery was completely drained after a day. When it is awake, it transmits fine.

The second one, No7, draws 2.0 uA, but when you turn it on it draws 170 mA, which is enough to generate heat, and it does not transmit. So we let it sit like that for a while and then feel the various parts It turns out to be the RF oscillator, U9, that's faulty. Further inspection reveals that the unused pad under pin U9-1 has shifted over and is touching U9-2. By this time we knocked off the BGA-5 chip, and can't get another on there because of all the silicone.

We conclude that both circuits were damaged during experiments and encapsulation. We should try again.

[05-MAY-14] We have a batch of ten A3028Es, No40.12-41.7, and two A3028Bs, No40.9-40.10. They have been soaking in water for five days, with three lots of hot water to provoke internal condensation. We measure gain versus frequency and find it to be within 1 dB of nominal for all transmitters. Switching noise peaks are all in the range 20-24 Hz, peak amplitude 5 μV, average amplitude 2 μV. No sign of spikes on No40.12, which has amplitude 5 μV. Thus we have all twelve transmitters functioning perfectly.

[09-MAY-14] We have two A3028P rat pup transmitters. We put them in hot water yesterday and left them soaking while turned off. Here they are after blow-drying, along with a non-functional model we assembled earlier. The model shows how we want the antenna and leads of the A3028P to be arranged, in a plane. The two working prototypes have their leads and antenna coming coming off the circuit board at odd angles.

We hope to fix the direction of the leads in future assemblies. In water, we measured battery voltage and noise amplitude before soaking yesterday and obtained for No41.8 4.2 V and 9 μV and for No41.9 4.1 V and 8 μV. Today we obtain for No41.8 4.1 V and 7 μV and for No41.9 4.2 V and 10 μV. We measure frequency response and find it to be within 1 dB of nominal for both.

[12-MAY-14] No41.8 and 41.9 still transmit a strong signal. Analog gain is 30 dB too low. We backe both in the oven for half an hour and 41.8 recovers fully, showing correct gain with frequency, while 41.9 shows some improvement. Leave them in the oven.

[14-MAY-14] No41.8 and 41.9 now working well. Battery voltage is 4.1 V. Frequency response is within 1 dB of nominal.

[19-MAY-14] New batch of transmitters, No41.10-42.9 placed in hot water and allowed to cool and soak for four days. Today we measure frequency response. All are within 1 dB of nominal except for No42.2, which is 2 dB below nominal at 130 Hz, there being no bump in the response before the cut-off. We measure switching noise, and obtain this plot showing noise less than 5 μV and within the range 21-23 Hz.

[28-MAY-14] We receive a batch of 50 of our A3028 assemblies with A302801B circuit board from Advanced Assembly. Below is one of the x-ray images of the two BGA packages we received from them.

We program and calibrate ten circuits, and test the magnetic switch, which remains a BGA-5 in this version of the circuit board. All work fine. There is no sign of the problems we have had in the past with the BGA-5.

[09-JUN-14] We have two new A3028P pup transmitters No43.10 and 43.11. They have been soaking for four days in water. We used acrylic coating on the analog circuits prior to applying three coats of silicone by dipping. Batteries are sealed with epoxy then three coats of silicone by dipping. The antenna is 45 mm long and bent into a tighter loop.

In our faraday enclosure we obtain 100% reception from both transmitters when they sit on our antenna. We place No43.10 and an A3019D No29.12 on an A3015C Loop Antenna on our table. We place the transmit antenna loops right on the A3015C surface, so the batteries are on top. Reception is 100.0% for both. We place the battery side down. Now the A3028B batteris is between the receive and transmit antennas. Reception is 59.9% from the A3028P and 99.9% from the A3019D. The A3028P should be implanted with the battery facing the body and the antenna facing the skin.

We measure frequency response. Gain is within 1 dB of nominal from 0-250 Hz for both transmitters. We place in water to measure noise and battery voltage. For a few minutes, No43.10 shows transients up to full scale, with frequency a few Hertz. It settles down to an average of 28500 counts and 14 counts rms, so battery voltage is 4.1 V and noise is 9 μV. No43.11 shows no transients, battery voltage 4.1 and noise 10 μv.

We have fourteen A3028E transmitters 42.10-43.9. They have been soaking in water for ten days, including three hot-water soaks. No42.10 won't turn on. Frequency response of all remaining transmitters is within 1 dB of nominal. Switching noise is less than 3 μV for all. Transmitter No43.4 has a flaw in its blue lead. We have twelve that are ready to ship.

[13-JUN-14] We have 5 of A3028AV2 made with A302801C circuit boards. See here for photograph of top side. The two large holes are for the BR1225 battery. When we load the battery into these holes, it is centered perfectly on the square of the circuit board. Note barrier pads in top-right near X and Y inputs. We program four as dual-channel and one as single-channel transmitters. We use the new V4 firmware, which provides compiler directives to select A302801B and A302801C circuit boards. We measure gain versus frequency and find it to be within ±1 dB for all channels and frequencies.

[19-JUN-14] We receive an A3028AV2 on an A302801C circuit board with leads, antenna, and battery loaded, and new over-mold applied. See photograph below.

The A3028AV2 over-mold is 7.7 mm high and 13.6 mm square. With two coats of silicone, the device will be 8.2 mm high and 14.1 mm high. Two coats may not provide a reliable seal over the irregularities in the mold surface. With three coats of silicone, we should get a good seal, but the device will be 8.4 mm high and 14.4 mm square. Our hand-encapsulated A3028A is not rectangular. Its height is varies from 8.0 to 8.4 mm and its width from 13.4 to 15.3 mm.

We program and calibrate the over-molded circuit. It works well with an external battery. It does not work with its internal battery. The internal battery voltage drops from 2.5 V to 1.0 V when we close the internal battery switch. The battery is exhausted. We connect another battery in parallel. After a few minutes, the internal battery voltage has risen to that of the external battery. Roughly 0.3 μA flows into the circuit. We close the internal battery switch. The external battery supplies 56 μA through R1 (2.7 V / 50 kΩ). We turn on the transmitter. The external battery supplies 187 μA (56 μ + operating current of dual-channel transmitter). We conclude that the internal battery is exhausted.

[20-JUN-14] At one of our assembly companies, they find that the batteries we sent them a month ago are all drained of charge. We sent the batteries in anti-static foam, which is electrically conducting.

We note that the circuit board entering the over-mold is at a slight angle to the horizontal, as a result of tension in the antenna and leads. The antenna and leads emerge vertically and must be bent to go horizontal. Instead of soldering the leads through the holes, we now plan to solder them as shown below.

The pads two which the leads are soldered are all secured by through-plated holes. The leads are secured by a rivet of solder.

[25-JUN-14] Transmitters 43.12-44.7 have been soaking in hot and cold water for a week. We measure frequency response, reception, and noise. All give gain within 1 dB of nominal for 0-250 Hz, reception 100% in faraday enclosure, and noise less than 40 counts rms after dropping in water. The plot below shows the switching noise in a 32-s interval.

Peak switching noise is 6.4 μV. We see the second, third, and fourth harmonics of the switching noise clearly in the spectrum.

[02-JUL-14] We have A3028AV2 encapsulated in epoxy and silicone with no acrylic coating on the EEG amplifiers. We want to find out if the barrier pads of the A302801C layout, and its greater separation between the input and output components, will eliminate condensation faults without the acrylic coating. These five transmitters have been soaking in water for a week with four hot water charges. They are No45.1 (A3028D), No45.3 (A3028D), No45.5 (A3028A), No45.7 (A3028D), and No45.8 (A3028B). Thus all but the last one are dual-channel. We connect to our 20-MΩ sinusoidal source and find the gain of the dual-channel devices lies within 1 dB of nominal. The difference between channels is less than 0.2 dB. Device No45.8 has gain 1 dB higher than normal from 1-20 Hz, nominal gain 20-110 Hz, shows only a 1-dB increase in gain at 130 Hz instead of 3 dB, and has the correct cut-off frequency. We place No45.8 in parallel with one input of No45.5 and note that the two have the same response to within 0.2 dB up to 110 Hz, when No45.8 is 2 dB too low. None of the transmitters generate a square wave when left open-circuit.

[03-JUL-14] After twenty-four hour bake at 60°C, No45.8 has nominal gain from 1-110 Hz, shows only a 1-dB increase in gain at 130 Hz, and has the correct cut-off frequency. Yesterday, before baking, the gain was 1 dB higher than nominal from 1-20 Hz, which is within specification. The lack of a 3-dB bump in gain at 130 Hz is out of specification, but persists after baking. So far, these first five A3028AV2s, encapsulated without acrylic coating, show not sign of condensation problems. Peak switching noise for the five transmitters is 4 μV in the range 20-22 Hz with both channels of each dual transmitter agreeing about the amplitude of the switching noise.

We have A3028AV1 circuits encapsulated with acrylic, epoxy, and silicone, No44.8-44.14, No46.1-3, all A3028B single-channel mouse transmitters. These we made with wires soldered flat on the pads, as shown here. The result is leads that emerge in the correct direction without bending. Frequency response of all amplifiers within 1 dB of nominal. Switching noise 6 μV maximum. We measure volume by displacement of water and get 1.36 ml each. We measure by weighing in and out of water and get 1.45 ml. On average, around 1.4 ml. Mass is 2.7 g.

[31-JUL-14] We have 12 of A3028E-AB, No46.5-47.2 that have soaked in water for five days. We measure gain versus frequency, all are within ±1 dB of nominal. We measure reception, all are 100% in enclosure. We measure switching noise and all 20-22 Hz, 0-6 μV. All turn and off multiple times without error.

We have No45.11 A3028A with thermoplastic over-mold and one coat of silicone. The one coat leaves visible cavities around the electrode leads. We left it soaking in water for three days. Now its battery voltage is 2.0 V, reception is poor, and gain is 20 dB too low.

We have No48.1 A3028A with thermoplastic over-mold and three coats of silicone. There are no visible cavities in the coating. We left to soak for three days. Its battery voltage is now 2.7 V, gain versus frequency within 1 dB of nominal, and within 0.2 dB between channels. Switching noise is 1.2 μV at 19.5 Hz. Reception is good. Magnetic switch is working well.

The transmitter body fits in a rectangular volume 14.3 mm × 14.0 mm × 8.5 mm = 1.7 ml. The volume occupied by the transmitter is 1.6±0.1 ml. Our most compact hand-encapsulated A3028A has volume 1.4±0.1 ml. The three coats we applied to No48.1 increased its thickness from 7.8 mm to 8.5 mm. This accumulation agrees well with the 125 μm per-coat thickness specified in the MED10-6607 data sheet.

[13-AUG-14] We have 9 of A3028B, No40.8, 40.11, 47.3, 47.6, 47.7, 47.9, 47.10, 47.12 and 2 of A3028A, No47.4 and 47.13. They have been soaking for four days. All are within ±1 dB of nominal frequency response. All give 100.0% reception in enclosure. Switching noise is 8 μV for No47.4 (both channels the same). Others have less switching noise. Magnetic switches all respond well.

[03-SEP-14] We have 8 of A3028B-CC, No49.2, No49.5-No49.11. We note that 49.11 is labelled 49.3 so we apply colored silicone over the label to obscure it. All transmitters produce less than 8 μV of switching noise and have frequency response within 1 dB of nominal. Reception is 100.0% in a faraday enclosure.

[12-SEP-14] Transmitters A3028E-FB No42.8, 44.6, and 44.5 have failed at Philipps University, Marburg after eight weeks implanted. No42.8 works fine, except it keeps turning itself off. This circuit was one upon which we replaced U3 by hand. No44.6 and No55.4 have exhausted their batteries. Even if they were left on from the moment we shipped them, they should still be running. We suspect excessive current consumption, which is a problem we observed in some members of the batch of circuits from which these two were taken.

We have a new batch of 100 circuits in which U3 is a UDFN-6. They work fine, except two out of twenty so far have had a short between U3-1 and U3-6. The assembly house glued U3 in place, so we must remove it with pliers. We replace and the board works fine. We note that the spacing between U3-1 and U3-6 is too small. The U3-1 pad is too large. We create A302801D layout and reduce the pad from 19 mils to 16 mils.

[22-SEP-14] We have a batch of twelve transmitters No49.14-50.11. All have been soaking in water for three days. All have frequency response within 1 dB of nominal, perfect reception in a faraday enclosure, and switch noise less than 6 μV.

[23-SEP-14] We hear from Pishan at UCL that 44.10 had symptom "no signal" after implantation on 11-AUG-14. This transmitter was shipped on 03-JUL-14, so it is possible that, once it arrived at UCL, it turned on and has since exhausted its battery.

[01-OCT-14] We have transmitters A3028E-AB No50.14-51.13. The silicone has cured for two days, but we have not soaked in water at all. We must ship them today. All have gain within 1 dB of nominal, perfect reception. We ship all but No51.3 and No51.4, which stuck together during curing, so we must touch up the outer coat. Switch noise is less than 6 μV for all the transmitters we shipped.

[03-OCT-14] Transmitter 50.12 and 50.13 are encapsulated in acrylic conformal coating and silicone. We injected silicone under the battery twice and dipped four times. Battery voltage is 2.5 V for some reason, but frequency response is within 1 dB of nominal. We place in water. Two hours later, No50.13 still had nominal frequency response, but No50.12 is generating a 1-Hz full-scale square wave.

[06-OCT-14] Transmitter 50.13 has been sitting in water. Its gain is 20 dB too low when driven by a 20-MΩ source impedance. We connect it in parallel with another transmitter and the gain of both is now 20 dB too low. We drive 50.13 with a 50-Ω source and we obtain nominal gain at 10 Hz, 3 dB too low at 100 Hz, and 6 dB too low at 130 Hz. We place 50.12 and 50.13 in the oven at 60°C

[08-OCT-14] After 48 hours in the oven, 50.12 and 50.13 both perform perfectly.

[10-OCT-14] Put batch No51.14-52.13 in water. Kirsten tells us she is certain she forgot to put the acrylic coating on the circuit boards.

[14-OCT-14] Batch No51.14-52.13 still soaking in water, turned off. These are A3028V2 made with the A302801C circuit board. We check frequency response on all 14 transmitters and find it to be within 1 dB of nominal in all cases. We leave in hot water.

[15-OCT-14] We examine 50.12 and 50.13 closely. Both have many bubbles in the acrylic coating around the amplifier parts. We consider whether there is a reaction between the acrylic coating and directly-applied silicone dispersion. We apply two coats of acrylic to a bare circuit board, then coat with silicone and see no bubbles. We have observed such bubbles when acrylic coating is tacky due to drying out. Transmitters 50.12 and 50.13 were made with tacky acrylic. Each transmitter has a deep hole behind the battery terminal, leading to the interior space beneath the battery. We fill these holes with a syringe and leave to cure. We review our history of acrylic coating and condensation-related problems. We started applying acrylic in September 2013 with the A3019A/D transmitters. We saw an immediate reduction in the incidence of condensation problems after our four-day water soak. As we moved to water washing and complete acrylic coating, condensation problems disappeared. Thus we believe the acrylic coating solved the A3019 condensation problem. The A3028V2 introduces a new layout with barrier electrodes and more distance between EEG amplifier input and output. Both 50.12 and 50.13 are A3028V2s. We have had no condensation problems with this circuit until the 50.12 and 50.13. Our hypothesis now is that an imperfect acrylic coating (bubbles) combined with an imperfect silicone coating (holes) resulted in condensation problems even with the new A3028V2 layout.

[19-OCT-14] At ION, transmitter No13, we're not sure which batch, has failed after several days implanted with an ISL. Its last moments are shown here.

[20-OCT-14] Two more transmitters have failed at Philipps University, Marburg. The screen shot below shows the recording shortly before failure from transmitters No50.1 and No50.2.

The average value of signal No50.2 in this interval, and more clearly in later intervals around 170 s, is around 20,000 counts, which implies a battery voltage of 6.0 V. The maximum possible voltage supplied by our lithium primary cell BR2330 is 3.0 V. When the average converted value is 30% of the full scale, the X input to the ADC (pin U7-2, see schematic) must be only 30% of the ADC power supply (VA). But the average value of this X input is 1.8 V when the amplifier is working correctly. Thus the amplifier is damaged.

The high frequency noise on No50.2 at 37-38 s has power from 75 Hz all the way up to 255 Hz. At time 192 s, there is full-scale noise from 0-255 Hz. The gain of the amplifier at 255 Hz is only 1, so a full-scale 255 Hz implies a 2.7-V 255-Hz signal at the X input electrode. Assuming such an input is impossible, the amplifier must be generating this signal itself, which implies it is damaged.

The Philipps University experiment involves stimulating the brain with 20-V pulses, 40 ms apart, 0.1 ms duration, at 2 Hz, as well as more sustained stimuli every minute or two. The trace below shows two sets of pulses.

The pulses are around 2 mV peak to peak. The more sustained stimuli reach an amplitude of 4 mV. Looking at these traces, we see no reason to suppose that the input to our transmitter is being driven by a signal outside the absolute maximum ratings of op-amp U5. The inputs are clamped by diodes inside the op-amp to its power supply voltages. Nevertheless, if we were to apply 20 V through 10 kΩ to the X input, we would see around 17 mA flowing through these clamping diodes, which exceeds their maximum rating of 10 mA. Thus it is possible to damage the transmitter with a 20-V stimulus delivered through brain tissue. Damaged op-amps can develop erratic input offset voltages and consume excessive current. If U5 starts to consume 1 mA, VA will drop to 1.7 V and the ADC will stop working. It will produce only 0's or 1's. We see such intervals in the No50.2 recording. Furthermore, the battery will drain in about ten days.

[20-OCT-14] After two more injections of silicone, making six in all to fill the holes behind the battery terminals, we are satisfied that No50.12 and 50.13 are sealed, so we put them in water.

[20-OCT-14] Batch No51.14-52.13 has soaking since 10-OCT-14. This is the batch with no acrylic coating. Gain versus frequency is within 1 dB of nominal for all transmitters.

[21-OCT-14] We have No44.10 back from UCL. We shipped this device on 03-JUL-14 and Pishan implanted on 11-AUG-14, at which point she discovered that it would not turn on. We find the exterior silicone in perfect condition, the epoxy in perfect condition, and the leads also. we cut away enamel and epoxy to get to the battery terminals. The battery voltage is 0.13 V. We apply 3.6 V and 600 μA flows into the dead battery. We can turn on and off the transmitter easily. The analog input shows mains hum. We drop the applied voltage to 2.7 V. After a few minutes, off-state quiescent current drops to 7 μA. We turn on and current increases to 85 μA. This transmitter, when calibrated, had on-state current 79 μA and off-state current 2 μA. If we assume that we still have 2 μA flowing into the circuit in the off-state, then 5 μA is flowing into the battery, which means the on-state current is now 80 μA, which is very close to the original 79 μA. Our best guess as to why this transmitter failed is that it was left on and drained its battery.

[21-OCT-14] Silicone-encapsulated No50.12 and No50.13 have been in water for 24 hours. No50.13 shows −6 dB gain versus frequency, but normal bump and cut-off frequencies. No50.12 won't turn on. We strip silicone from the underside and measure battery voltage 2.6 V. Now it turns on. Gain is correct at 1 Hz and drops off rapidly above that, with random drifting baseline in the signal.

[21-OCT-14] We receive this diagram of the electrode arrangement at Philipps University, Marburg.

[20-OCT-14] Batch No51.14-52.13 has been in water since 10-OCT-14. Gain versus frequency remains within 1 dB of nominal. We switch cold for hot water. We measure switching noise and perform harmony test. All transmitters appear to be perfect. We leave them switched on and in water.

[22-OCT-14] Batch No51.14-52.13 all running, noise is normal. Average voltages are between 69% and 71% of full scale.

[22-OCT-14] Batch No52.14-53.13 has been sitting in water for 5 days. Noise is normal. Reception is perfect. Gain versus frequency within 1 dB of nominal except for 53.7, which is 1 dB below nominal at 140 Hz. Magnetic switches all reliable.

[24-OCT-14] Batch No51.14-52.13 has been running in water since 20-OCT-14 and soaking since 10-OCT-14. Noise is normal. Average voltage is 70% of full scale. Frequency response within 1 dB of nominal.

[27-OCT-14] Batch No51.14-52.13 has been running in water since 20-OCT-14 and soaking since 10-OCT-14. Average voltage is 70% of full scale except for 52.1, which is at 84% of full scale, with occasional steps lower or higher. The battery voltage appears to be around 2.1 V. When we apply a 10-mVpp input, we see saturation and inversion of the positive cycles at the top end of the amplifier's dynamic range. We reduce the amplitude to 3 mVpp and observe frequency response within 1 dB of nominal. Reception is 100.0% within our faraday enclosure. All others show perfect reception, normal switch noise, and frequency response within 1 dB of nominal.

No52.1 We remove silicone and release the +ve battery tab. We measure 2.27 V between the circuit VB pad and the positive battery tab. When we connect with an ammeter, we observe 1.6 μA in the inactive state and 7 mA when we switch on. At 7 mA, the battery would last only 36 hours, but 52.1 ran for four days with no change in battery voltage. We burn off epoxy over the -ve battery hole and connect 2.7 V. Inactive current is 1.9 μA, active current fluctuates between 12-15 mA. We connect 2.7 V directly to VD (using R4). Current is 13 mA. We activate and deactivate the magnetic switch. Current remains unchanged. After a few minutes, current is 9 mA. We increase the supply to 3.9 V and current increases to 20 mA, then drops over a few minutes to 15 mA. We remove U1 to make sure we have no current going back to the magnetic switch. Current is 16 mA at 3.1 V. We remove R4 and current is 14 mA at 3.1 V. Signal output is stuck at 0, but reception is perfect. We observe bursts of 910-MHz power every 2 ms in the RFPM Instrument. We compare spectrometer plot with an encapsulated transmitter and find peak power to be within a few dB. We remove U9. We now have no RF output, but current is 18 mA at 2.7 V. Remove U4. Current remains 18 mA at 2.7 V. We remove C3. Current drops to 20 μA, the correct quiescent current of U7 if supplied with 1.8 V. We are holding C3, preparing to measure its resistance and capacitance, when it shoots out of the tweezer tip and vanishes.

[28-OCT-14] Transmitter 50.5 has failed by discharging its battery while implanted at Philipps University. Looking at their recordings, it appears that a No7 transmitter is about to fail also.

According to the engineers at AVX, excessive leakage current in capacitors is caused by internal cracks, but its manifestation can be delayed by several months. The capacitor can be cracked during pick and placement at the assembly house, during depanelization, and during subsequent soldering near the capacitor. According to Ikeo et al. (Failure Mechanisms that Cause High Electrical Leakage in Multilayer Ceramic Capacitors), ceramic capacitors can fail by degeneration of their insulation layers resulting their behaving like resistors of a few hundred Ohms. The cause of degeneration they investigated is a voltage-driven chemical reaction assisted by the penetration of water and chloride ions into the capacitor through cracks or microscopic pores.

When we solder the antenna onto the A3028 circuit board, we use zinc chloride flux (acid flux) and high temperature. Capacitor C3 is the power supply decoupling capacitor for the radio-frequency oscillator. We give the location of this capacitor for various transmitters in the following table.

| Version | Capacitor | Distance to Pad (mm) |

Distance to Board Edge (mm) |

|---|---|---|---|

| A3019 | C7, 1nF | 0.36 top side | 0.33 |

| A3028V1 | C3, 1nF | 1.6 bottom side | 2.4 |

| A3028V2 | C3, 1nF | 1.0 bottom side | 0.41 |

| A3028R1 | C3, 1nF | 0.58 bottom side | 2.1 |

We shipped hundreds of A3019s and never observed this sudden discharge problem, even though we soldered with acid flux directly on the circuit board next to the capacitor, and we broke the circuit boards apart from one another by hand. This suggests that the problems with the capacitors on our new circuit boards is not with our soldering procedure, but either at the manufacturer or at the assembly house. We shipped a hundred A3028V1s and may have observed one such failure at ION recently (No13 see 19-OCT-14). The A3028V2 assembly we have been shipping since late September has shown 1 such failure out of 14 in our office, and at least 3 such failures out of 14 at Philipps University. Transmitter 50.7 may be failing the same way as we write. Transmitter 50.2 showed full-range oscillations at hundreds of Hertz, which could be caused by a leaky capacitor for C11.

We recently started cleaning the boards with a finer brush, which may be getting under the capacitors and cracking them. We will stop using this brush. We will examine all 1-nF capacitors on our A3028V2 boards for cracks. We will pre-tin the steel leads, wash them, and solder them with normal flux to the circuit boards. This will reduce the amount of chloride near the decoupling capacitor. But we suspect that we will see no cracks, because the cracks are internal, and that the damage was done during assembly, before the boards ever arrived at our office. Thus we will replace C3 on all boards.

[29-OCT-14] Transmitter 50.7 failed today at Marburg. Of the batch of 12 we sent them, 4 have failed by sudden battery drain and 1 by something crazy in the EEG amplifier.

We inspect the 1-nF capacitors on the bottom side of half a dozen A3028V2 circuit boards. These are C3, C9, C10, and C11. The figure below shows C9 and C10 on the circuit board with assembly company serial number ending in 049.

Looking closely at the top side of C9, we see a chip on the edge and a semi-circular mark. This mark is, we believe, the outline of the vacuum pick-up bit used to place the capacitor during machine assembly (see Figure 7 here). When too much force is exerted by the bit, such marks appear on top, and cracks occur on the bottom. Any crack in a capacitor is a means by which moisture can penetrate and, when voltage is applied, cause degeneration of the insulation.

Meanwhile, batch No51.14-52.13 has ben running in water since 20-OCT-14 and soaking since 10-OCT-14. No52.1 drained its battery two days ago. No further failures have occurred.

[30-OCT-14] Batch No51.14-52.13 has been running in water since 20-OCT-14 and soaking since 10-OCT-14. Thirteen of them remain working. Battery voltage is 2.66 V on average with standard deviation 16 mV. Frequency response is within 1 dB of nominal for all devices except 52.6, which has gain 1.5 dB above nominal at 140 Hz. We place transmitters 45.1, 45.3, 49.12, 49.13, 51.3, 51.4, 52.14, 53.13 in water, all turned on. We checked some of their frequency responses, and all of their battery voltages. We turn on acrylic and silicone encapsulated 50.3. Its gain versus frequency is once again with in 1 dB of nominal. We leave it running in water also.

We place a transmitter on a horizontal antenna in a faraday enclosure. We measure the power picked up by the antenna in four different orientations of the antenna. We do this with two mouse transmitters and receive up to −44 dBm from one and −40 dBm from the other. We repeat with three rat transmitters and receive a maximum of −42 dBm and −40 dBm from each. We perform the same experiment, but the transmitter is in a jar of water resting on the antenna. We receive up to −42 dBm from a mouse transmitter and up to −40 dBm with a rat transmitter. We placed the transmitters in a small petri dish of water. We obtained up to −36 dBm from a rat transmitter and −38 dBm from a mouse transmitter.

[03-NOV-14] Transmitters No51.14, 52.2-52.13 have been running in water since 20-OCT-14 and soaking since 10-OCT-14. Transmitter No52.6 generates its own sinusoid of amplitude 13,000 counts at 100 Hz when its input is driven by 0V through 20 MΩ. With inputs open-circuit, frequency drops to 80 Hz and amplitude increases to 22,000. When driven by a 10-mVpp, 50-Ω sinusoid, gain is 6 dB too high, but the shape of the gain versus frequency is within 1 dB of nominal. When connected in parallel with another 51.14 to 60 mVp-p through 20 MΩ, the gain versus frequency of the two transmitters is identical and correct. On its own again, with 20 mVp-p through 20 MΩ and we no longer see a square wave, but gain is 10 dB too high at 100 Hz. Place in parallel with No52.7 and gain versus frequency for the two is identical but 10 dB too high at 120 Hz. We put No51.14 in parallel again with 60 mVp-p through 20 MΩ and get identical gain, but gain is 7 dB too high at 120 Hz. Reception for No52.6 is perfect and noise is normal when in water. This transmitter has the square wave problem, and it appears to be varying in its severity as we perform our experiments. Transmitters No51.14, 52.2-52.5, 52.7-52.13 all have gain within 1 dB of nominal, perfect reception, and normal noise. In water, average signal is between 66% and 69% of full scale, indicating battery voltages 2.60-2.73 V.

Transmitters 45.1, 45.3, 49.12, 49.13, 51.3, 51.4, 52.14, 53.13 have been running in water since 30-OCT-14. Transmitters 45.1 and 45.3 are both dual channel. The figure below shows the frequency response of both channels in parallel for 45.1.

For similar plots for other transmitters see No45.3 (dual channel also), and No49.12, No49.13, No51.3, No51.4, No52.14, No53.13. All are within 1 dB of nominal, with No49.12 having gain 1dB above nominal at 120 Hz. Transmitter No50.13, which is acrylic and silicone coating, has gain 14 dB below nominal at 1 Hz, and 20 dB below nominal at 120 Hz.

Batch 54.1-54.10 has been running in water for three days. Average signal values 67-68% of full scale. The same is true for dual-channel 54.13 and 55.1. We measure gain versus frequency for the dual channel transmitters and find it to be within 1 dB of nominal.

[06-NOV-14] After baking, transmitter No52.6 shows gain versus frequency within 1 dB of nominal except at 120 Hz, where it is 1.5 dB above nominal. We set this one aside as a demonstration transmitter.

[07-NOV-14] After a total of five days running in water, we ship transmitters 52.14, 53.13, 54.3, and 54.4 to ION for job 1161.

[10-NOV-14] We have transmitters 49.12-13, 51.3-4, 54.1-2, 54.5-10, 55.1 (two-channel) running in water for a total of 4 + 5 = 9 days. Average signal values are all 67-69% full scale, except for 51.3, which is at 73%, indicating a battery voltage of 2.45 V.

No51.3 We check gain versus frequency for 51.3 and find it within 1 dB of nominal. Battery voltage remains 2.45 V. Silicone encapsulation looks intact all around. No sign of condensation inside. We remove silicone and disconnect positive battery terminal. We measure inactive current 1 μA and active current of 550 μA. We remove C3. On current is now 600 μA. We remove C5 and on current drops to 80 μ. We measure the capacitance of C5, it is 9 μF. Insulation resistance is greater than 20 MΩ. According to here, "Failed capacitors frequently recovered their insulation resistance at high temperature (above +200°C)." When we removed C5 with a soldering iron, we heated it to 400°C.

We hear from ION that 53.3 and 53.6 have failed after three days implanted, following a 5-day active soak. We do not yet know the nature of the failure. We place 49.12-13, 51.4, 54.1-2, 54.5-10, 55.1 in a jar of water in the oven at 60°C. All are running.

We receive from Philipps transmitters 43.3, 43.7, 50.1, 50.2, 50.5, and 50.9, all A3028Es. No43.3 Antenna is cut, red lead cut short. Reception 100%, picking up mains hum, average value with mains hum is 40,000. Gain versus frequency within 1 dB of nominal. Severe discoloration of purple enamel. No43.7 Reception 100%, picking up mains hum, average value 43,000. Gain versus frequency within 1 dB of nominal. Severe discoloration of purple enamel. No50.1 Reception 0%. Large cut across silicone on battery side. Open up encapsulation. Battery voltage is 2.1 V. Apply external 2.6 V. Inactive current 2 μA, on current 80 μA. Reception 100%, picks up mains hum. No50.2 Reception 0%. Open up encapsulation. Battery voltage 2.4 V and falling. Active current 2 μA, inactive current 80 μA. Picks up mains hum. Average signal 41.700 with 2.8 V applied. No50.5 Reception 100%, picking up mains hum, average value 51,000, gain versus frequency within 1 dB of nominal accounting for low battery voltage. Open up encapsulation. Battery voltage 2.4 V steady. Inactive current 2 μA, on current 80 μA. No50.9 Reception 0%. Open up encapsulation. Battery voltage 2.4 V and falling. Inactive current 2 μA, on current 7 mA. Reception when on is 100% and picks up mains hum. Heat up and then remove C3, C5, and C4. When we remove C4, on current drops to 80 μA.

[11-NOV-14] The average battery voltage today for 49.12-13, 51.4, 54.1-2, 54.5-10, 55.1, after 14 hr at 60°C running in water, is 2.83 V with standard deviation 0.025 V. Later in the day, after 24 hr at 60°C, No49.13 average value is at 90% of full scale, and No54.2 is at 73% of full scale. The others are still normal.

[12-NOV-14] Transmitters 49.13 and 54.2 are both draining their batteries. No49.13 Reception 100%. Open up encapsulation. Battery voltage 2.2 V. Inactive current 2 μA, on current 80 μA. No54.2 Reception 100%. Open up encapsulation. Battery voltage 2.4 V. Inactive current 550 μA, on current 600 μA. Remove C6, C5, C2. After removing C2, inactive current is 2 μA and on current is 80 μA. Later in the day, 54.6 is at 64% while the others remain at 68%.

[13-NOV-14] No54.6 does not transmit. Transmitters 49.12, 51.4, 54.1-2, 54.5, 54.7-10, and 55.1 all have average signal 67-69% of full scale. They have been running in water at 60° for a little over three days. We turn them off, dry them, and put them in the oven to recover. The black enamel of No54.6 has a pale discoloration. We open up the encapsulation. Battery voltage is 2.4 V. Inactive current 2 μA, on current is 1.5 mA. We heat up C5 with a lump of solder, but do not remove it. On current drops to 80 μA.

[21-NOV-14] We have batch E55.5, E55.6, B55.10, B55.11, A55.13, E56.1, E56.2, and D56.3 (the letter gives the version). We encapsulate without acrylic coating. We use DP270, a black potting epoxy with 60-minute work life. We coat four times with silicone. We turn them off and place in water on the morning of 19-NOV-14. Today we measure frequency response. All are within 1 dB of nominal, except for channels D56.3X, E55.6, E56.1, A55.13X, which have peak gain 1 dB higher than nominal. We put them back in water.

[25-NOV-14] We have batch R60.1-14 encapsulated with acrylic, EP965L epoxy, and four coats of silicone. We measure gain versus frequency and find it within 1 dB of nominal except for R60.1 and R60.2, which have gain 1 dB too low at 140 Hz. Reception is 100% for all transmitters. We calibrate our spectrometer with 910 MHz and measure center frequencies for R60.1-14 and obtain 920, 920, 920, 917, 923, 917, 919, 916, 917, 919, 916, 918, 918, 920 MHz respectively. Transmitter R60.5 is the one at 923 MHz. Switching noise is less than 4 μV for all devices. We place in water in the oven at 60°C at 9:00 am.

[26-NOV-14] Batch R60.1-14 have been running in water at 60°C for 36 hours. We replace 60°C water with 20°C water. Average signal values are 64-66% of full scale. Gain versus frequency within 1 dB of nominal. Reception excellent from all 14 simultaneously on one antenna. Switching noise normal. We apply three more coats of silicone to R60.5. The result is unattractive. We return all of them to the oven.

Batch E55.5, E55.6, B55.10, B55.11, A55.13, E56.1, E56.2, and D56.3 has been soaking in water at 20°C for one week. We measure frequency response. All are within 1 dB of nominal. We note that this batch has no acrylic coating. We turn them off and put them in hot water.

[28-NOV-14] Batch R60.1-14 have been running in water at 60°C for 72 hours. We cool them down. Battery voltages are normal, gain versus frequency is within 1 dB of nominal for all fourteen transmitters, noise is normal. We turn them off and put them back in the oven in a tray to dry out.

[03-DEC-14] Batch E55.5, E55.6, B55.10, B55.11, A55.13, E56.1, E56.2, and D56.3 has been soaking in water at 20°C for two weeks. Frequency response is within ± 1 dB of nominal, except D56.3X, E55.6, and A55.13X, which have peak gain 1 dB higher than nominal. Average values 44-45k, except A55.13 which is at 47k. We turn them off and put them in hot water.

[05-DEC-14] Rob Wykes at ION turned on Batch 52 and put them in water at 60°C for three days. At the end, he made the following observations.

We advise Rob that all four of the transmitters that were inactive upon removal are most likely faulty. This brings to 23 the total number of A3028E-ABs we must replace for ION.

[05-DEC-14] We have Batch R61.1-14 of A3028R-AB devices encapsulated with acrylic, epoxy, and silicone. We turn them all on and poach them for two hours at 60°C. Average signal value is 64-66% of full scale. We return them to the oven, running in water at 60°C.

[08-DEC-14] Batch R61.1-14 has been running in water at 60°C for three days. We put them in cold water. Average signal value is 64-66% of full scale, except 61.14 which is 69% of full scale. Switching noise less than 6 μV. Gain versus frequency within 1 dB of nominal for all devices.[11-DEC-14] Batch E55.5, E55.6, B55.10, B55.11, A55.13, E56.1, E56.2, and D56.3 has been soaking in water at 20°C for three weeks. Frequency response is within ± 1 dB of nominal, except D56.3X, E55.6, and A55.13X, which have peak gain 1 dB higher than nominal.

[15-DEC-14] Batch R62.1-14 has been running in water at 60°C for four days. We checked that they were all transmitting and that switch noise was normal after a few hours in water, but did not measure frequency response before the poach. Today we find that all transmitters are still running. We get 100% reception from all of them. R62.10 has gain 1 dB too low at 120 Hz. R62.6 has gain 3 dB too low at 120 Hz. R62.12 transmits all zeros. We bake these three for an hour. The symptoms of R62.10 and R62.12 remain unchanged. But the gain of R62.6 is now within 1 dB of nominal. We ship all but R62.6 and R62.12. We put R62.6 in water to soak at room temperature.

[18-DEC-14] We take this picture of batch B63.1-14. Reception for all transmitters is 100.0% in our faraday enclosure. Frequency response is within 1 dB of nominal. We turn them all on and put them in water at 60°C.

[19-DEC-14] All transmitters B63.1-14 are still running. Average signal value between 45500 and 46000 (69.4-70.2% of full scale). Noise is on average 22 counts rms (9 μV). We turn them off and put them back in water at 60°C.