Implantable Light-Emitting Diode (A3036IL) Manual

Implantable Light-Emitting Diode (A3036IL) Manual

© 2019-2025 Kevan Hashemi, Open Source Instruments Inc.© 2021 Alice Hashemi, Open Source Instruments Inc.

| Description |

| Versions |

| Optical Power |

| Design and Development |

Note: The Implantable Light-Emitting Diode (A3036IL) is an active product. The Implantable Stimulator-Transponder (A3036) is discontinued, replaced by the Implantable Stimulator-Transponder (A3041).

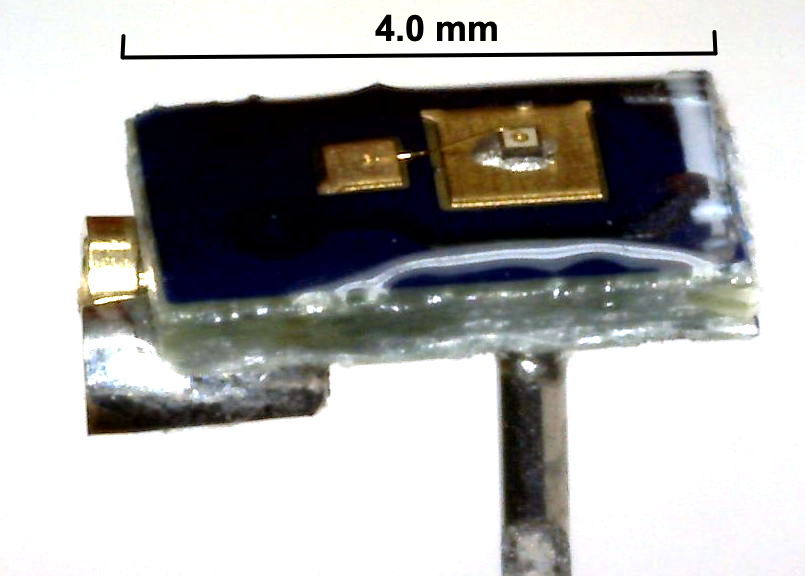

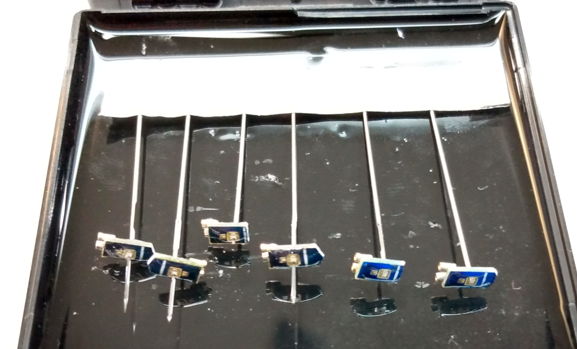

[09-JUN-25] The Implantable Light-Emitting Diode (A3036IL) is a light-emitting diode (LED) designed for implantation in animals so as to provide optical stimulation for optogenetic experiments. They are accessories to our Implantable Stimulator-Transponders (ISTs), such as the A3041. The A3036IL uses a variety of LEDs: the blue and green EZ500, blue and green EZ290, and the deep red LXZ1-PA01. All A3036ILs are equipped with a thin-walled steel tube to allow the LED to be mounted during implantation. The tube is thinned near the base so it may be cut after the LED has been secured.

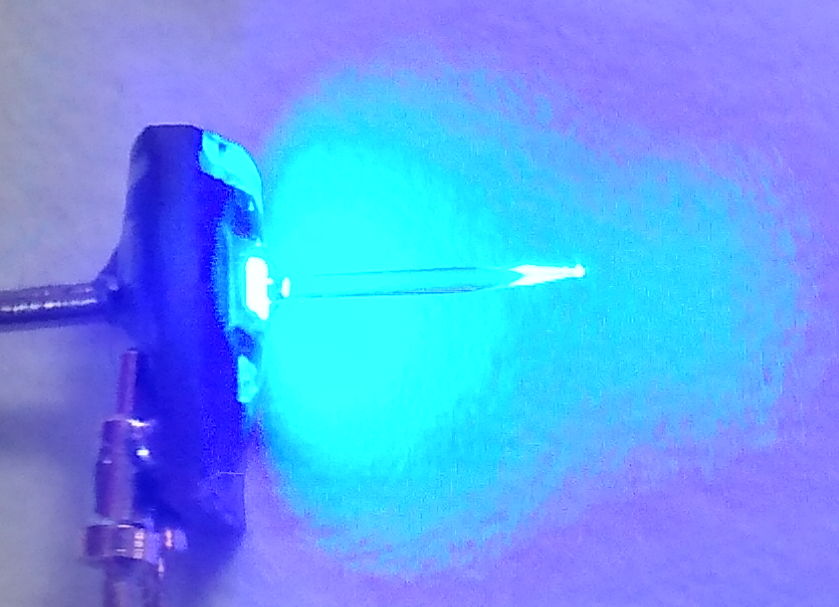

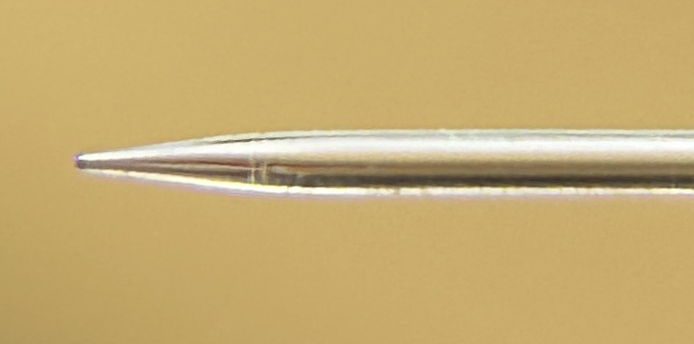

The optical fibers we use with our implantable LEDs are polished at the base and tapered at the tip. We glue the polished base to the surface of an LED and the fiber carries LED light to the tapered tip. We call the combination of fiber and LED a Fiber-Coupled LEDs (FCLEDs). The fraction of optical power emitted by the LED that is delivered to the tapered tip of the fiber is the coupling efficiency of the fiber.

We make FCLEDs out of bare LED chips wire-bonded to a printed circuit board. We have blue and green FCLEDs, but no red FCLEDs, because we have not yet found a red LED of adequate efficiency that we can purchase in die form.

With no optical fiber glued to the LED, the LED is instead covered with clear epoxy so that it may be placed on the surface of the tissue to be illuminated. We call these our Surface-Mount LEDs (SMLEDs). The surface of the epoxy may be flat or domed, but this makes little difference to the power delivered to the tissue surface. These epoxy-topped LEDs we call Surface-Mount LEDs (SMLEDs). We make red, blue, and green SMLEDs.

A steel mounting tube is glued to the back of each ILED and thinned just above the glue joint so it may be cut easily during implantation.

[03-AUG-22] The following versions of the Implantable Light-Emitting Diode (A3036IL, ILED) are in production. The gold-plated pins on the end of the stimulator's leads mate with a pair of sockets on the A3036IL. Currently, we use wire-bonded EZ500 chips for our blue and green illuminators, both SMLED and FCLED. We use the LXZ1-PA01 for our red SMLEDs. For a comparison of a larger variety of illuminators, including those we have rejected for inferior performance, see Optical Power.

| Version | Type | LED | Light Guide | Wavelength (nm) |

Die Size (μm × μm) |

Optical Power (mW at 10 mA) |

|---|---|---|---|---|---|---|

| A3036IL-A | SMLED | Blue EZ500 | Epoxy Dome | 460 | 480 × 480 | 10.3 |

| A3036IL-B | SMLED | Green EZ500 | Epoxy Dome | 527 | 480 × 480 | 7.2 |

| A3036IL-A270-4 | FCLED | Blue EZ500 | 270 μm Dia, 4 mm Len | 460 | 480 × 480 | 2.8 |

| A3036IL-B270-4 | FCLED | Green EZ500 | 270 μm Dia, 4 mm Len | 527 | 480 × 480 | 1.8 |

| A3036IL-A270-6 | FCLED | Blue EZ500 | 270 μm Dia, 6 mm Len | 460 | 480 × 480 | 2.8 |

| A3036IL-B270-6 | FCLED | Green EZ500 | 270 μm Dia, 6 mm Len | 527 | 480 × 480 | 1.8 |

| A3036IL-A450-8 | FCLED | Blue EZ500 | 450 μm Dia, 8 mm Len | 460 | 480 × 480 | 3.3 |

| A3036IL-B450-8 | FCLED | Green EZ500 | 450 μm Dia, 8 mm Len | 527 | 480 × 480 | 2.4 |

| A3036IL-E | SMLED | LXZ1-PA01 | Epoxy Dome | 650 | 1000 × 1000 | 8.0 |

| A3036IL-X | SMLED | Any | Epoxy Dome | Any | Any | Test ILED |

We can make any taper-tipped, polished-base fiber 4 mm or longer, diameter 270 μm, 330 μm or 450 μm.

The EZ500 data sheet does not provide spectra for their light emission. But the Luxeon Z data sheet from Philips Lumileds does provide spectra, which we present below. We assume the EZ500 blue and green spectra are similar.

Based upon the above spectra, we estimate that the half-power width of the EZ500 460-nm blue LED is 20 nm, and of the 525-nm green is 50 nm.

[09-JUN-25] The following table compares the optical power output of at 10 mA forward current for various combinations of fibers, domes, and LEDs. For all these devices, optical power is approximately linear with current. Notice that the EZ290 fiber-coupled LEDs are not as efficient as the EZ500, even though the surface area of the EZ290 is smaller. The central bond wire of the EZ290 interferes with the contact between the fiber and the emitting surface.

| Version | Type | LED | Light Guide | Wavelength (nm) |

Die Size (μm × μm) |

Output (mW at 10 mA) |

|---|---|---|---|---|---|---|

| A3036IL-A | SMLED | Blue EZ500 | Epoxy Dome | 460 | 480 × 480 | 10.3 |

| A3036IL-B | SMLED | Green EZ500 | Epoxy Dome | 527 | 480 × 480 | 7.2 |

| A3036IL-A270-4 | FCLED | Blue EZ500 | 270 μm Dia, 4 mm Len | 460 | 480 × 480 | 2.8 |

| A3036IL-B270-4 | FCLED | Green EZ500 | 270 μm Dia, 4 mm Len | 527 | 480 × 480 | 1.8 |

| A3036IL-A270-6 | FCLED | Blue EZ500 | 270 μm Dia, 6 mm Len | 460 | 480 × 480 | 2.8 |

| A3036IL-B270-6 | FCLED | Green EZ500 | 270 μm Dia, 6 mm Len | 527 | 480 × 480 | 1.8 |

| A3036IL-A450-8 | FCLED | Blue EZ500 | 450 μm Dia, 8 mm Len | 460 | 480 × 480 | 3.3 |

| A3036IL-B450-8 | FCLED | Green EZ500 | 450 μm Dia, 8 mm Len | 527 | 480 × 480 | 2.4 |

| A3036IL-C | SMLED | Blue EZ290 | Epoxy Dome | 460 | 290 × 290 | 7.4 |

| A3036IL-D | SMLED | Green EZ290 | Epoxy Dome | 527 | 290 × 290 | 3.9 |

| A3036IL-C450-8 | FCLED | Blue EZ290 | 450 μm Dia, 6 mm Len | 460 | 290 × 290 | 3.8 |

| A3036IL-D450-8 | FCLED | Green EZ290 | 450 μm Dia, 6 mm Len | 527 | 290 × 290 | 2.0 |

| A3036IL-C270-6 | FCLED | Blue EZ290 | 270 μm Dia, 6 mm Len | 460 | 290 × 290 | 1.8 |

| A3036IL-D270-6 | FCLED | Green EZ290 | 270 μm Dia, 6 mm Len | 527 | 290 × 290 | 1.0 |

| A3036IL-E | SMLED | Red LuxeonZ | Epoxy Dome | 650 | 1000 × 1000 | 8.0 |

| A3036IL-X | SMLED | Any | Epoxy Dome | Any | Test ILED | >2.0 |

We calibrate our implantable LEDs by measuring their optical power output when the current through its LED is 10 mA. We measure the LED's power output with one of our calibration stands. We have one calibration stand for bare LEDs and another for fiber-coupled LEDs. The LED output power is approximately proportional to current, as shown in the plot below. We get roughly twice as much power at 20 mA and half as much at 5 mA.

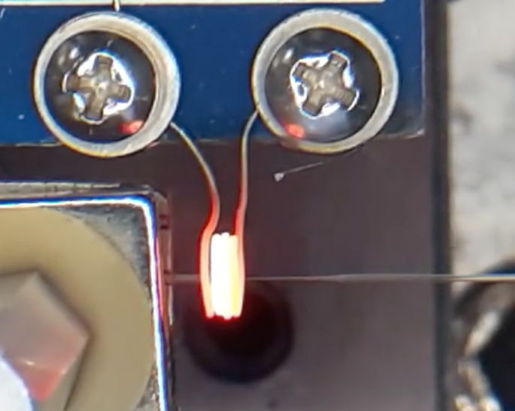

Our Implantable LEDs (A3036IL) generate light with an LED mounted on a printed circuit board. Our favored LED is the EZ500, which comes in blue and green. The EZ500 light-emitting surface is 480 μm square, with a bond wire to one side, so that we can lower the base of an optical fiber right onto the emitting surface for greater coupling efficiency. For red light, we use the LXZ1-PA01 from the Luxeon Z family, which provides a 1-mm square emitting surface. The LXZ1-PA01 is an efficient source of 650-nm deep-red light for illuminating the surface of organ tissue. But its emitting surface is too large for efficient coupling of light into an optical fiber.

Blue LEDs produce roughly 1 mW/mA (one milliwatt per milliamp forward current), green LEDs roughly 0.5 mW/mA, and the deep-red LED roughly 0.8 mW/mA. We make surface illuminators by covering the LED with a clear epoxy dome. The A3036IL-A is a blue C460EZ500 with clear epoxy dome for surface illumination of brain tissue. We make depth illuminators by gluing a glass fiber with a tapered tip to the LED and inserting the tapered tip to the required depth. Roughly one third of the light emitted by the LED is captured by the polished, flat base of the fiber and transported to its tapered tip, where it radiates in all directions. We make the tapered fibers by polishing one end of a high-index optical fiber, and tapering the other end with the help of our custom tapermaking machine.

The A3036IL-A270-4 is a blue C460EZ500 with a 4-mm long, 270-μm diameter fiber light guide. The A3036IL-A270-4's average power output at the fiber tip is 2.8 mW for 10 mA forward current.

We measure optical power using an SD445 photodiode and an ammeter. We convert photocurrent into optical power using 0.18 mA/mW for 460-nm blue, 0.25 mA/mW for 527-nm green, and 0.40 mA/mW for 655-nm red light. We have two calibration stands that permit us to make consistent measurements of power for any combination of LED and fiber. The drawing below shows the arrangement of LED or FCLED and photodiode in each stand. For more information on the calibration and appearance of the test stands, see our development notes.

When we cap an LED with epoxy, we make sure the surface is convex. We avoid loss by total internal reflection within the epoxy, and we direct the light more in the forward direction, which favors illumination of a surface directly in front of the ILED. But the epoxy dome is never uniform, so measuring the power emitted by the ILED after application of the epoxy dome is difficult. We assume the total power transmitted by the ILED is equal to the total power emitted by the LED die before we apply the dome.

We measure the power emitted by fiber-coupled LEDs directly with our FCLED calibration stand. The fraction of LED power reaching the fiber tip depends upon the area of the fiber and the LED, and upon the numerical aperture of the fiber itself. We make our light guides out of optical fiber with numerical aperture 0.86 (core index 1.72, cladding index 1.49). All light within ±60° of the fiber axis will be captured by the fiber and transported to the tip. For a typical LED, this ±60° accounts for 75% of the light emitted. A 450-μm diameter light guide, perfectly polished at the base, and perfectly positioned on a 480-μm square EZ500 LED will couple 51% of the emitted light to the fiber tip. The A3036IL-A8 uses a 450-μm fiber on a C460EZ500, and we obtain coupling efficiency of around 40%.

The Implantable Stimulator-Transponder (A3041B) boosts its battery voltage to a fixed 3.3 V. It also provides a current limit we can apply to the stimulus. When equipped with 45 mm long leads, each will have resistance 28 Ω, making a total of 56 Ω. Suppose we turn up the stimulus current to its maximum value of 10 mA. To determine the actual LED current we need to know the approximate forward voltage drop of the LED at 10 mA.

The A3036IL-A450-8 FCLED has forward voltage 2.73 V at current 10 mA. The voltage drop across 56 Ω at 10 mA is 0.56 V. Thus 3.29 V is enough to drive 10 mA through the leads and LED. At this current, the tip of the fiber produces 5 mW. Thus the maximum optical power from the FCLED when driven by the A3041B is 5 mW.

[09-JUN-25] For design files and development logbook, see the A3036 design and development page at D3036.