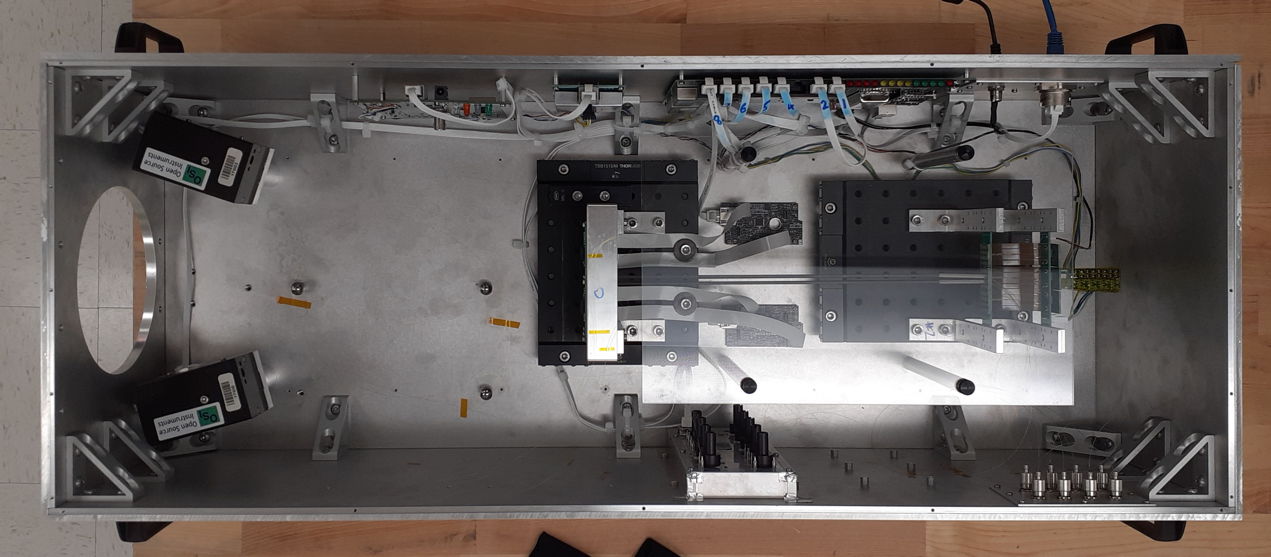

Our Direct Fiber Positioning System (DFPS) uses the slight bending of a piezo-electric cylinder to displace an optical fiber at the end of a tube. Each fiber positioner consists of a cylindrical, piezo-electric actuator, a hollow tube that acts as a mast, and two or more optical fibers held in a ferrule at the tip of the mask. Accompanying the positioner are controller electronics that generate the actuator's ±250-V electrode voltages. One of the fibers is a guide fiber, which we use to determine the location of the mast tip. The remaining fibers are detector fibers, which we use to collect light from celestial objects. The DFPS provides one fiber positioner per 5 mm × 5 mm square area. The control electronics for each positioner fits beneath its 25 mm2 footprint. All positioners can be adjusted independently and simultaneously with no increase in power consumption. We can construct an array of eighty thousand positioners using the same fundamental design as we would use to construct an array of eighty fibers. Positioners share power and serial communication with their neighbors, so the number of electrical connections required by a large array of positioners remains small. For more information, see the DFPS Manual.

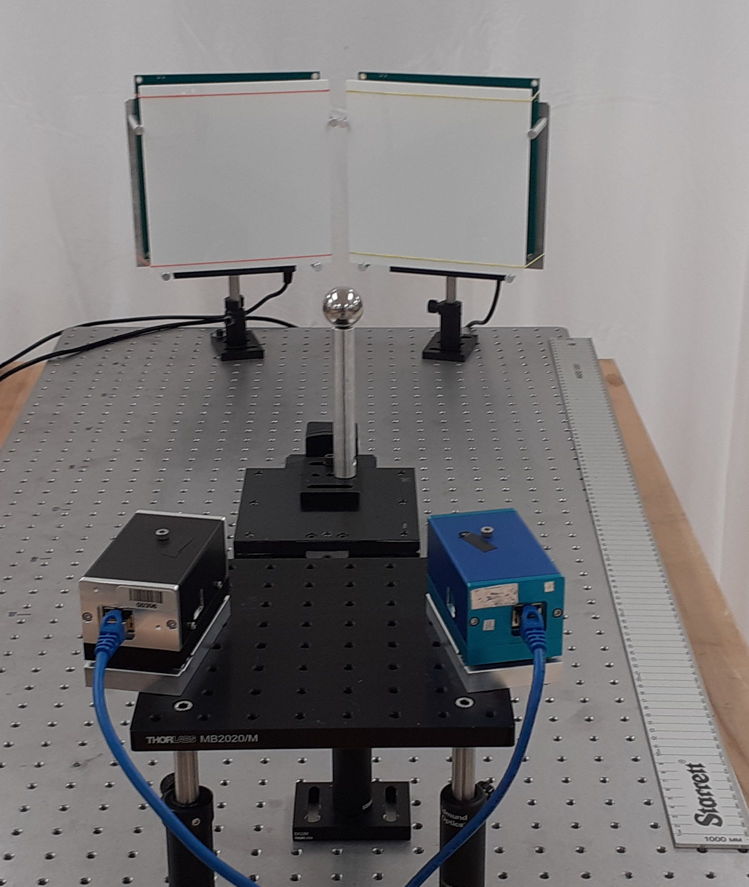

Our Contactless Position Measurement System (CPMS) measures the position and orientation of highly-reflecting components during assembly in a clean room. The target application for this instrument is the Superconducting Radio Frequency (SRF) string assembly for particle accelerators. The CPMS measures the position of components that are to be fastened together, and robots move the parts into contact and screw them together, without any human having to handle the components. For more information, see the CPMS Manual.